備/投影儀殼3.jpg)

As we all know, with the rapid development of society, various situations have promoted the enrichment and diversification of se…… MORE

With the continuous improvement of plastic processing and modification skills, the application scope has expanded rapidly. Diffe…… MORE

Generally, the plastic shell of the power supply is made of plastic material. Of course, some industrial power supplies use hard…… MORE

In fact, the plastic shell has already penetrated into people's life and work, bringing us a lot of convenience. The plastic she…… MORE

療器材類/美容儀器殼8.jpg)

There are many materials used in the manufacture and production of medical device shells, such as ABS, PP, PE, stainless steel, …… MORE

備/監(jiān)控器1.jpg)

In the early years, the choice of smart cameras limited to industrial and commercial applications has gradually entered our live…… MORE

1. The plastic shell must be placed neatly in the box, and the number of each layer must be uniform. 2. Do not squeeze the plast…… MORE

療器材類/測血壓外殼.jpg)

In the processing of medical device shell, the first thing to do is to carry out blanking processing. When the good blanking is …… MORE

Most of the burrs on the plastic shell of the power supply occur on the parting surface, that is, where the molten material flow…… MORE

In the production process of plastic shell, some unexpected situations will inevitably occur, resulting in some defects of the p…… MORE

The cracking of plastic injection products includes filiform cracks, microcracks, white tops and cracks on the surface of plasti…… MORE

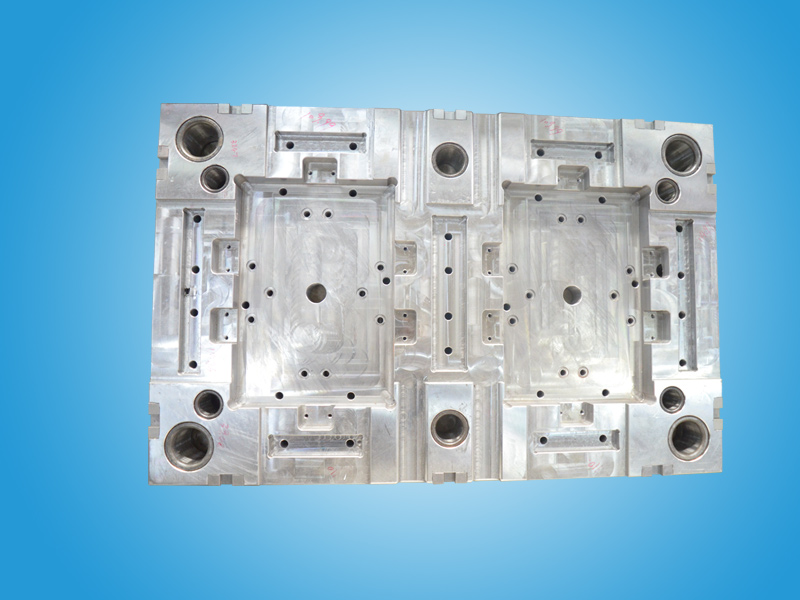

The external and internal shapes of plastic parts are directly formed by the cavity and core. The processing of these complex th…… MORE